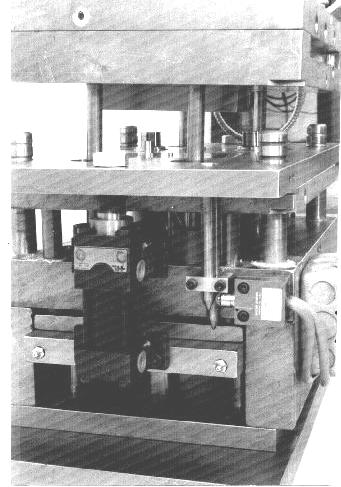

Figure 3 shows a mold with the cores forward in the collapsed conditions. At this point, the plastic part can be stripped from the core with a secondary stripper plate near the center of Figure 3. In this case the stripper plate is operated by hydraulic cylinders. The sequence of operations is programmed with switches signaling the controller when the plates are in the desired position. Two of the switches are shown in Figure 3 the right side of the mold just below the centerline.

|